| Model | FIRE-PROFILE1800 |

| Input voltage, V | AC220±10%, 1-Ph, 50/60Hz |

| Modes of cutting | Gas cutting |

| Cutting thickness range, mm | 5-150 |

| Cutting speed, mm/min | 50-750 |

| Diameter of cutting circle, Ø mm | 20-1800 |

| Template mounted on template holder | Any profile within 30mm to 700 mm dia. circle |

| Template mounted on centre shaft | Any profile within 700 mm to 1800 mm dia. circle |

| Length of cutting line, mm | 1650 |

| Magnet tracing roller, Ø mm | 10 |

| Electric motor | DC110V, 24W, 3600r/min |

| Speed control | SCR |

| Control pointer | FWD-OFF-REV toggle switch |

| Speed control | Continuous variable by a rotary knob |

| Tracer | Clockwise & Anti-clockwise |

| Cutter movement | Vertical movement by rack and pinion |

| Template position | Mounted on template holder or central shaft |

| Accuracy, mm | ≤1.5mm |

| Cutting torch | Injector type to suit acetylene/LPG |

| Dimensions (LxWxH), mm | 1190x335x800 |

| Weight, kg | 58 |

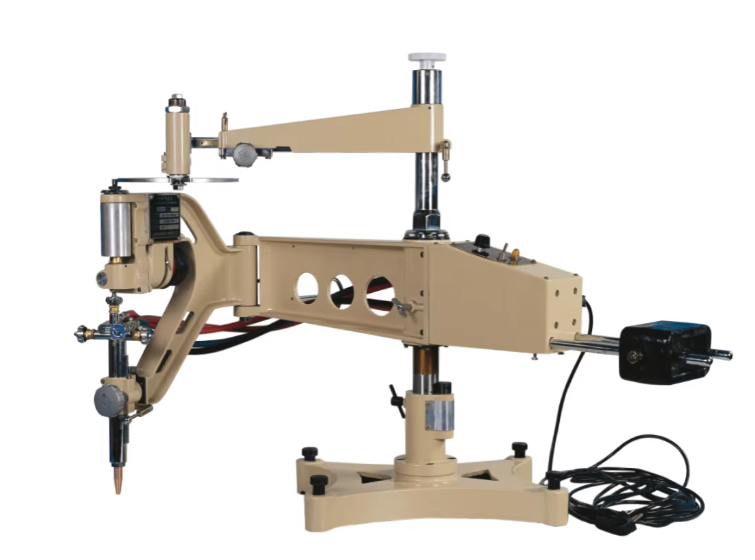

Profile Cutting Machine

- Ideal for repetitive jobs, continuous cutting with steel templates.

- The machine has a compact design, simple and efficient to operate, and is very economical.

- The ball base allows you to easily place the device on a plate.

- The speed of the machine can be changed with an indexed selector knob.

- It is well designed and made of “A” grade cast alloy.

- The speed control system adopts integrated circuit adjustment to ensure smooth operation.

- The extremely strong permanent magnet roller ensures accurate fitting to complex template shapes by preventing slippage during operation. Since this machine uses the SCR control system, the cutting speed is thoroughly stable.

- The speed can be uniformly adjusted within the specified range without changing the motor performance.

- The gas distributor is made of pure copper material, which has long service life and high efficiency.

- The sample holder can be adjusted freely for accurate and efficient profiling. So you can cut any shape and any size in bulk in the same shape in a short amount of time.

- A portable and robust profile cutting machine is suitable for both field jobs and factories.

- It has a wide range of applications and can be used with equal ease in boilers, shipyards, infrastructure industries, metallurgy industries, small workshops, and other fields.