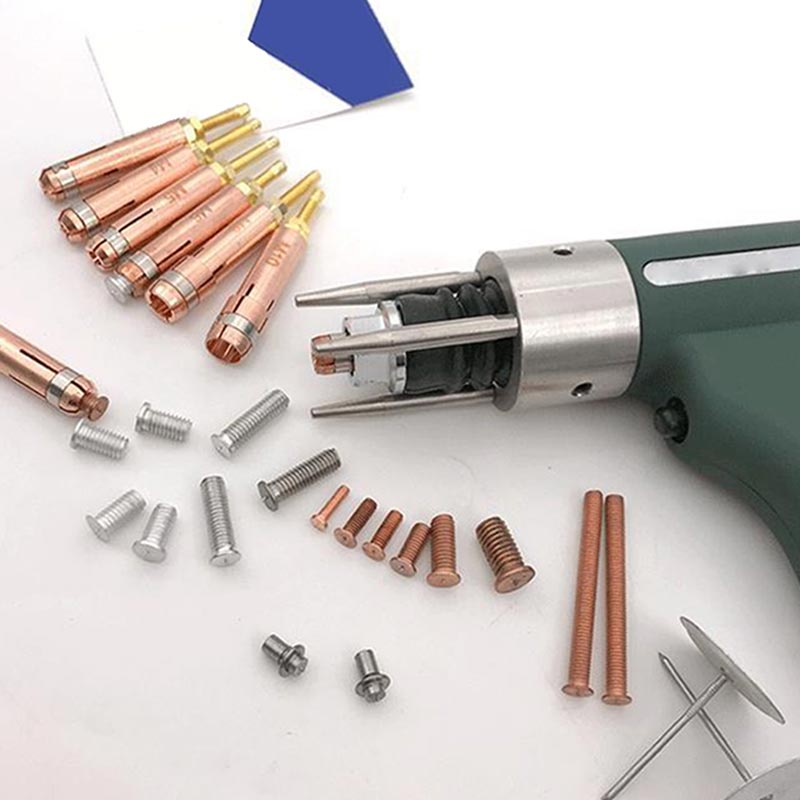

With our powerful CSW Series Stud Welders, every stud fixing is super easy!

The CSD series are high-performance arc stud welding systems designed and built by Fireweld. These drawn arc stud welding machines are efficient, robust, easy to handle with braked wheels, and have the ability to weld in different locations depending on your requirements. Ideal options for fixing large diameter mild and stainless steel studs to sheet metal.

The Fireweld legacy stud welding machine is suitable for studs from 6 up to 25mm and allows a maximum current of 2500A. With a time-setting range of up to 2000 ms, this compact machine offers the possibility of flexible applications and robust housing in addition to operational safety.

Features

- Suitable for stud diameters 6 – 25 mm.

- Significant energy savings of up to 35%.

- High welding current up to 2500A.

- Continuously adjustable 100-2500 amps.

- Timing control 15-2000 milliseconds, stepless.

- Allow ±20% voltage fluctuation.

- Accurate welding time and welding current adjustment.

- Excellent short cycle performance in thick and thin base material.

- Suitable for construction sites.

- Ideal for mobile use – significantly less weight than conventional stud welding units.

- Thanks to the innovative cooling concept, a high duty cycle and thus fast welding processes are insured.

- The Fireweld drawn arc welder offers the highest duty cycle, largest stud diameter, and longest cable length.

- The trolley version of the FIRE-2500 with two large, extremely robust, and detachable wheels and a telescopic handle is ideal for mobile use on construction sites.

- Widely used in steel structure buildings, bridges, locomotives, shipbuilding, boilers, industrial furnaces and other fields.

| Specifications | FIRE-2500 |

| Welding range, mm | 6 to 25 |

| Rated input power, KVA | 120 |

| Maximum output current, A | 2500 |

| Welding current range, A | 100-2500, continuously adjustable |

| Welding method | Drawn arc (ceramic ferrule), short cycle |

| Main circuit | Full bridge controlled rectifier |

| Control circuit | Micro-processor controlled |

| Rated input current, A | 162 |

| Rated welding voltage, V | 32 |

| Primary power, V | 380/415v, 3ph, 50/60Hz |

| Welding time, sec | 0.01-9.99 |

| Length of weldable stud, mm | ≤400 |

| Efficiency, % | 85 |

| Degree of protection, class | IP23 |

| Insulation, class | H |

| Welding material | Mild steel, stainless steel, aluminum |

| Cooling | Air cooled |

| Dimensions (LxWxH), mm | 780x355x870 |

| Weight, kg | 130 |